Sleeping well at night is essential as well as a strong bed is a crucial element in the process of a good night’s sleep. Strengthening bed slats on your bed can be accomplished through the addition of Slats. However, there’s more you could use to increase the strength of the slats to ensure uninterrupted sleeping.

In this tutorial, I’ll show you how to strengthen the slats of your bed, which will ensure you get the best sleep that is possible. How to make bed slats stronger?

What are Bed Slats? And what is their function?

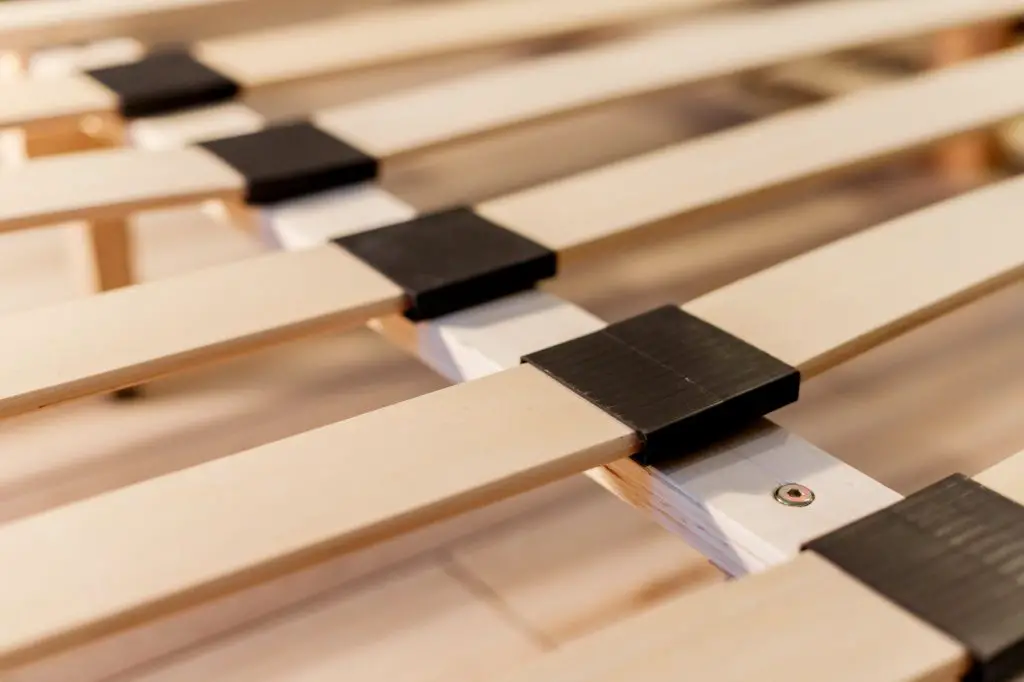

The bed slats can be found in platform beds. They extend horizontally along the frame of the bed and serve to assist in the support of the mattress. They are usually made from wood. But, slats made of metal are not uncommon.

Bed slats perform two main functions. They first provide an area for a mattress. In other words, where should you place the mattress?

Additionally, they assist in spreading the weight evenly of the mattress and users of the bed throughout the frame. The spread reduces the chance of breaking a frame.

Bed Slats And Their Types

The bed slats are constructed within platform beds. They are standing horizontally on the bed frame. They are generally used to create the platform for the mattress. Slats are typically made of wood. It is also not typical to see slats of steel. It’s best to learn how to repair broken bed slats yourself.

Solid-Slatted Platform

Solid slats that can be constructed from metal or wood, act as a solid support for mattresses. Slats made of wood are typically made from pine. On the other hand, the metal ones are generally made out of aluminum.

To ensure the longevity of your firm mattress, you need to use it in conjunction with a mattress made of firm foam to stop unintentional sagging in the course of the course of. A combination of slats as well as a firm mattress with support will provide a comfy and lasting sleep surface.

Sprung-Slatted Platform Beds

Sprung slats are made using malleable types of wood that stop cracking and stress. Beech is among the most sought-after woods used to construct bed frames as well as slats. The reinforced slat system is made of beech and is a straight upward arch.

The platform bed provides a bounce feature to your mattress. The bounce of the lightweight wooden slats allows them to be more open to the body weight of the user. Furthermore, a solid mattress isn’t required for this model.

Basic Frame

The basic bed frame is made up of an underlying beam. The slatted construction for this type of bed is typical and is less slatted compared to another bed frame.

Why Do Bed Slats Become Loose Or Shaky?

Understanding why the bed slats get loose is just as important as knowing how to build stronger fix bed slats. The looseness or instability of a bed slat could result from any one of these:

Great Risk Of Bed Frame Damage

If you are constantly shifting the wooden bed frame location the risk is that it can cause damage to the bed frame. This constant movement may loosen the joints, or cause slats to become smaller due to friction.

Squeaky Bed

The loose beds, more frequently, make an eerie sound. This is uncomfortable on the part of household members.

Preventable Accidents

A unsteady slat that is positioned on the bed frame of your bed poses the risk of serious injury, since it could slide off. The result could cause accidents and could cause injury to people who live close near the bed.

8 Common Reasons Why Bed Slats Always Break

The bed slats become weak wood due to various causes. There are a few reasons for this. Wooden bed slats break regularly:

- Wood with a weak structure

- With thin wooden bed slats

- The joints are loose.

- The bed is loud and squeaky

- A weak central support beam

- There is no link between the bed frame and the frame

- There is no central wood beam for support

- The bed’s total of slats does not meet the requirements.

10 Ways How to Make Bed Slats Stronger

There are nine ways you can make your bed’s slats more durable for an extra durable bed frame, and better sleeper security.

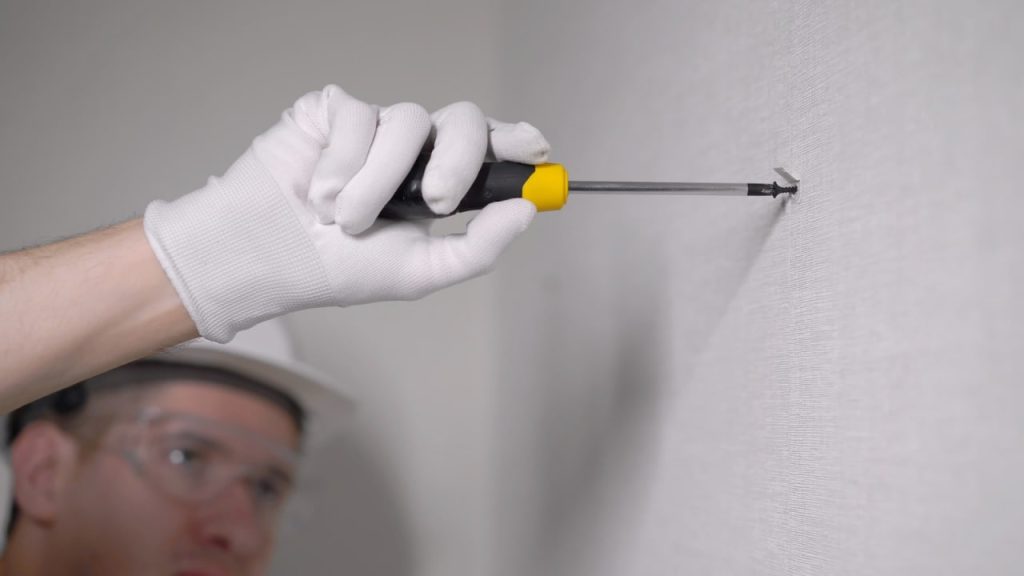

1. Important: Secure the slats to the bed frame

There are beds with slats which rest on rails without being secured. The problem is that these slats are able to slide easily and increase the chance of concentration of weight and broken frames/slats.

The slats can be screwed down to solve this issue once and all. Alternately, you could fix the slats down using nails. The project requires 2 or 1/2-inch wood screws as well as an electric drill to complete this project.

Alternately, you could make use of smooth-shanked nails as well as an hammer, if you choose to not to run the nail along the slats. If using screws, you should begin by drilling holes in the slats.

After that, insert the screws in the holes, then secure them into the slats of the railing. The use of nails can be a little tricky because nailing directly to the raised railings could weaken the bed.

Furthermore, removing the fix bed slats for moving is more challenging if bed slats have been nailed to the rails on your bed frame. However, nailing can make your bed frame stronger and prevent slats from moving.

0.75-inch plywood is the ideal choice to create stronger bed slats. Pick a heavy one to help evenly distribute weight across the bed slats.

2. Recommend top the bed slats with plywood

A great alternative to nailing or screwing down slats is to cover them with plywood. The piece of wood helps prevent the plywood from slipping as well as providing a stronger foundation for mattress support.

Thus, it decreases the possibility of mattress slumping. However, the only disadvantage is the price. The average price for a sheet is $20. Some kinds of plywood sheet may be as high as $70.

It is necessary to have a saw, tap, tape measure,, drill as well as a pencil to complete this task. Naturally, you’ll require screws and plywood. We would recommend 0.75-inch plywood.

Begin by assessing and cutting enough wood for the size of the slats reinforce the bed. After that, lift the structure of the slats off the bed. Then, begin fixing or nailing the wood.

Make sure to join the plywood pieces left to right instead of the top, side rails and bottom, if there is multiple pieces. Put the reinforced Slats system to the frame of the bed.

Thus, the entire job of covering bed slats using plywood is about $50.

Tools Need

- 0.75-inch plywood

- Drill

- Saw

- Measuring tape

- Pencil

3. Use slat spacers to prevent the slats from shifting

Maybe you’re not looking to fix the slats to the frame of your bed considering that this can make it difficult to take down the bed.

Tools Need

- Wood planks (same wood as current slats)

- Saw

- Measuring tape

- Pencil

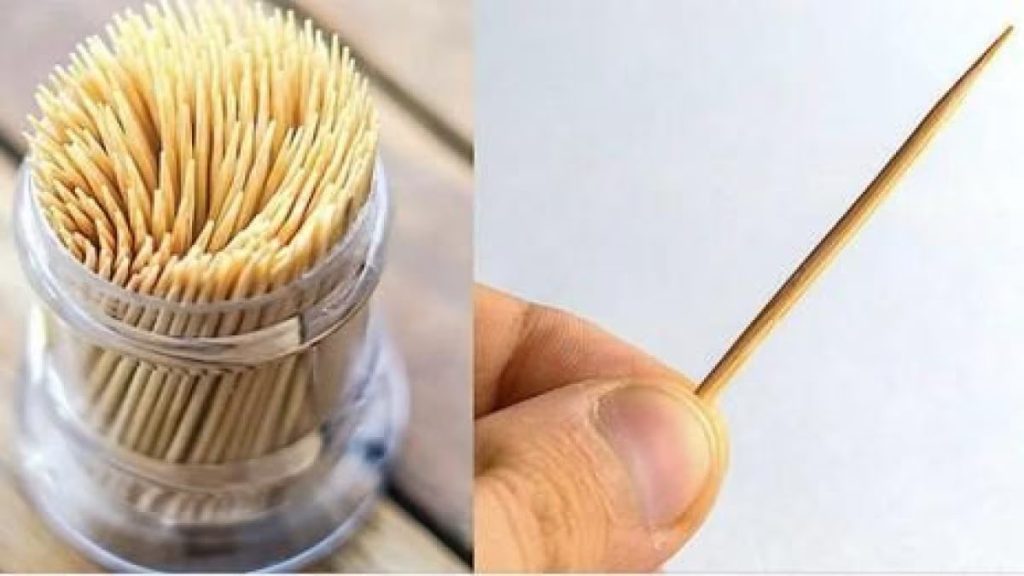

In the same way, it is preferential not using screws to attach plywood onto slats. Another option to keep the slats properly spaced is to use the slat space.

Slat spacers are small items placed between the slats that are already in place to keep their movement. It is possible to purchase them on the internet or build them by yourself. We recommend that you make these slats spacers at home for time savings and to reduce costs.

There is a lot of ease to create and utilize Slat spacers. Start by purchasing a wooden slats plank that is about the same width as the bed’s slats. After that, cut it into pieces that are as wide as the space you would like between the bed slats.

Then, place the slat spacers on the rails, putting them in between all the slats. When you’ve removed all the spacers, and you’re happy with their design, place wood glue on the bottom of each spacer. Then, place it back in place, then press it until it sticks firmly.

4. Add more slats/pull the slats closer

The three suggestions below attempt to solve this issue, without changing the structure of existing slats or the bed frame. There comes a time when the structure of sinking mattress and the slats is shaky and the bed reinforcement kit weak.

Fixing down, adding wood or adding spacers the bed the more slats may not be enough to solve the issue. Therefore, it is important to explore other options. Other guidelines on this list will provide alternatives to the problem.

We recommend first trying to include additional slats in order to “help out” the existing slats slabs. The addition of new slats accomplishes two things: strengthening the slat structure that is already in place as well as spacing the existing more slats out to ensure equal and even weight distribution throughout.

Start by determining the amount of more slats needed. In general, you will require another plank to go between two planks. Take the measurements.

How wide and long do they need to be? In addition, how thick must they be? The length and thickness must correspond to the current planks.

Decide on which type of wood you’d like. The most sought-after selection. You can then order additional planks screw plywood and fix them onto the slat framework already in place.

Tip: Pinewood is a popular option for introducing new plansks in a bed because they’re durable and easy to use.

5. Replace/reinforce a weak/saggy center beam

The central support beam is essential to maintaining the bed’s stability and sturdy. It can also stop sagging frames and may help to prevent the more slats from slipping.

Naturally, not every bed comes with one center support beam. But, larger beds typically come with a central support. The weak center support beam, in the center is one of the major reasons for sagging beds.

Perhaps the supportive center beam is already delaminating? Perhaps, even more importantly, you be suffering from a damaged or broken center beam. Doing too much on a bed that has the center beam broken is extremely risky.

There are two choices: strengthen the beam you have or take it off and replace the beam. It is best to strengthen the beam if your beam is strong, however it is slightly saggy. Choose a solid wood plank made of lumber that’s about four inches long, and then attach it to the beam.

But, if your beam has become damaged It is recommended to repair it as strengthening it will leave you with an unsecure link.

6. Important: Add a supportive center beam

It is also possible to make platform beds that include a center bean that is supportive on your mattress. The center beam could run across the entire length of your mattress. It is able to pass across the wood slats. It is necessary to search for 8-10 inches of 2×8 timber along with 30 pieces of screw for platform bed and frames.

The bed should be lifted and then tilted it over to the side. Begin to determine the length of the bed from beginning to the end of a slat. Take these measurements and copy them onto the 2×8 planks of wood and then cut the planks.

Take a measurement of 12 inches away from the base of the beam, and then stain those locations. Attach the leg support to the locations marked on the 90-degree angle of the beam.

Tips: Be sure to reduce the legs so that they are equal to the length of the legs. Place your bed frame onto the beam, and then nail it to the beam. Now you have a more sturdy framework.

7. Replace the slats with thicker lumber

Another option for reversing damaged or sagging platform bed slats is to completely replace them. It can be a costly task. It’s also necessary for repairing broken slats.

The replacement of the broken slats are the only method to restore bed frame strength and function. Two things we recommend. The first is to consider changing the slats to more robust lumber.

Then, think about stronger wood. A majority of hardwoods can do well. But, planks of oak could be the ideal alternative to pine wood because they’re easy to locate and extremely durable.

Decide how many slats require. You can also look into replacing the entire frame of slats. 2-inch thick 2×4 planks make ideal, but 2x8s or even 2x10s can be good enough.

Reduce the wood according to the dimensions of the original oak planks used, and start replacement of the broken or damaged slats. It is possible to use screws or nails to attach the planks of wood to the frame of your bed; it’s up to you.

Do not leave a lot of space between the slats, or eliminate gaps completely.

8. Recommend replace wood slats with metallic slats

Metal slats offer a better option than wooden slats. However, some wood species offer the same level of quality and durability. However, they’re typically extremely expensive and can cost you several hundred dollars when you purchase them.

Additionally, you won’t have the hardwoods that are harder in the hardware stores of your local. Metallic slats cost less and are widely accessible. Once you have decided then, purchase the metal slats square metal tubing at the local hardware shop or machine shop. The most effective type of metallic slats is square.

Request the shop to cut the tubes for the price. In the event that you don’t, you’ll require the help of a hacksaw, grinder or a circular saw fitted with an iron blade that can cut the tube of metallic slats to the proper size. Drill holes through the metallic slats tubes according to the dimensions of the bed frame and attach the tubes to the new bed frame itself.

9. Buy a box spring

It is also recommended to look into a boxspring as well as the bed’s slats by changing slats or adding slats made of metal.

Box springs have a lot of similarities to the plywood. They actually perform exactly the same thing, providing the platform bed or foundation for the mattress. There is a major difference: the box spring is more robust as well as stronger. It also looks similar to the mattress.

A common box spring sometimes referred to as a mattress made of box springs, includes a light wood or steel frame stuffed with coils of steel that are wrapped in cloth. This is similar to putting the mattress, which is smaller and stronger beneath the actual mattress.

The installation of a boxspring on your bed frame is straightforward. To begin, take off the mattress made of foam and place the bunkie board at the foundation of your bed frame.

After that, place the box spring onto the top and take the foam mattress back. You can also lay the bunkie boards over your used box spring mattress. The major disadvantage of not all beds made of box springs is that they’re significantly more costly than underlayments made of plywood.

We recommend solid wood products It is believed that oak Pine, Hickory, Birch, Ash, Beech and Birch are all excellent, strong timbers to build bed slats. They are strong in compressive as well as strength for bending.

10. Use a Thicker Mattress

It is possible to use a more dense mattress for extra support. It also stops your mattress from making loud sounds.

However, first you have to repair the bed slats stronger that are broken slats or repair the sagging on the wobbly bed slats stronger. The use of a mattress with a higher density will give you more help.

The thickness of a mattress can reduce the force that is applied to the thin bed slats stronger. The more bed slats the stronger are prevented from breaking due to excessive force. In addition, bed slats should be more able to support capacity.

A mattress that is 10 inches in thickness will help strengthen bed slats the mattress slats. The 12-14-inch size is the best choice if you want to sleep on your side, providing the added benefit of cushioning.

Even even with thin bed slats stronger getting a mattress with a higher density is perfect to distribute the weight evenly across all the bed slats stronger, without causing the reinforced bed slats stronger break more.

How to make bed slats cheaply

The easiest method of making bed slats is using 0.75-inch-thick plywood. Make plywood into 1’4 planks. Drill the holes from one end before putting in bed slats in the frame of your bed.

These are the steps you should follow when creating bed slats the most inexpensively,

- Determine the bed’s size and the number of slats you will be required to

- Get wood, drill and screws, nail and a saw

- Take measurements of the length and width of the frame

- Mark and measure 0.75-inch thick planks of 1’4 lumber that are 0.75 inches thick.

- Wood for sanding

- Varnishing and sealant the wood

- Installing wooden bed slats

When To Replace Your Bed Frames

If these methods don’t result in a sturdy bed frame, it’s time to change it. Below are some indicators which will tell you that when it’s time to change the frame of your bed:

- A mattress that sinks

- Center beam broken bed slats stronger that is currently attached to the bed frame

- Bed frame that is weak or bed slats that are wobbly

- Squeaking, squeaking loudly, and making noises

- Restlessness

| Wood Bed Types | Capacities (maximum weight) |

| Wooden bed frame | 600 lbs. |

| Plywood bed | 150-200 lbs. |

| Wooden box spring | 45 lbs. |

How To Make Center Support For Bed Frame?

The center support beam can be made for your bed frame by using the following steps.

- Take mattress off and bed.

- The bed should be lifted and leaned it up against the wall

- The distance should be measured from the head to the base of the slat bed. Also, keep track of the length that the beams of wood.

The length of the standard wood beam for twin is approximately 77-inches and 82-inches for queen size and king sizes.

- The distance you measure is from to the foot of the bed frame to the top of the leg for the bed frame.

The length that is recommended for the standard should be 8-10 inches. You can subtract 1.5 inches to determine the length of the supporting legs. This is about 6.5-8.5 inches.

- Make sure you measure and mark 2’8 with the pencil and the square.

- Make the beams of wood and posts to form supportive center beam legs.

- Do a 12 inch measurement from each end of the beam made from wood and draw a line on the beam.

- Leg supports can be secured with nail or screw that are 90 degrees in angle with the beam of wood.

- Reduce the length of the leg support in order to make them the same size as the frame’s legs.

- Position the bed frame on top of the beam. beam.

- Be sure to put the middle of the supporting beam in two central lines that intersect at the assister position.

- Fix the support beam in the middle to the frame of the bed using nails or screws.

Tools Need

- 810-inches of 2´8 wood plank (same wood and thick as current slat spaces)

- 30 3-inch screws

- Three supportive center beam posts for legs

- Measuring tape

- Pencil

- Square

The whole project cost approximately $10.

How Do I Keep My Bed Slats From Breaking?

The bed can be kept frames from bending,

- Installation of slat spaces

- Top bed slats of plywood

- Attach the bed slats securely to the frame of your bed

- Make more slats available by pulling them closer

- Rebuild or replace the broken center beam

- Create a strong center beam

- Include the bed with slats that are thicker

- Replace bed slats made of wood by slats made of metal slats

- Replace slats and slats with wood that is stronger

- The top bed slats are crafted from box spring

These are the most effective ways for strengthen bed slats.

The first couple of points specifically focus on strengthening bed slats. The next points are an additional step to enhance the durability of the bed slats.

How Do I Reinforce Bed Frame Legs?

It is possible to strengthen bed frame’s legs by tightening joints in the wood that are loose, with stronger and more robust bed frame legs and including beams that support. Bed frame leg that are reinforce bed frame legs are able to distribute weight more evenly and support more weight, without losing their stability.

The bed frame reinforced with reinforcement stops your metal slats bed frames from making sounds, or wobbling. They also improve the durability of your metal bed frames. Sleep well when you reinforce the bed frame’s legs.

Can You Make Bed Slats Out Of Plywood?

Yes, you can create bed slats using plywood. Choose 1 inch or greater plywood in order to preserve the durability of the lightweight wooden bed slats.

Bed frames made of plywood are designed to support weight effectively. Drill or screw properly, and then tighten using sturdy wooden slats joints.

The first step is to measure the bed frame’s length and length and width. After that, cut 1’4 inch thick 1-inch planks of wood slats and insert them in the bed frame prior to drilling.

Can You Add Slats To A Bed Frame?

It is possible to put thinner slats on the frame of a bed for strength and improve its longevity. Before adding the existing slats onto a bed frame, choose a sturdy wood for bed slats. Then, pre-drill the frame of the bed to connect bed slats with ease on the frame of your bed.

Conclusion how to make bed slats stronger

Sleeping well is crucial. But, if you’re faced with the unfortunate situation of an unsatisfactory bed frame or bed slats that are broken bed slats or wobbly bed slats, you’ll need repair the issue.

If you now know how to make your thin all the bed slats more sturdy, you won’t need to purchase a brand fresh bed frame to ensure the comfort and ease.

FAQ how to make bed slats stronger wood

Why do my bed slats stronger keep breaking?

Slatted mattresses often cause pain and may indicate inadequate support or inadequate sizes. Using slats can secure slats. Alternatively, you could attach these slats straight onto a frame to keep the slats from damaging the beds overall flexibility.

How much weight can bed slats hold?

Typical wood slats will support between 500 and 800 pounds. For added weight and stability slat reinforce are recommended for heavier mattresses or metal bed frames that permit the addition of additional slats.

How do you support a slatted bed base?

Using the Ledges and Center rails or Cross Rails to support the slatted bed base is possible. The kit is compatible with wood or upholstery box spring mattress, not metal beds. The Strong Duty Crossrail Kit is perfect for people who don’t want to have the entire rail installed on bedframes.

What Kind Of Wood Should You Use For Bed Slats?

It is recommended to use solid, hard, sturdy robust, durable, and sturdy wooden bed slats. It must be able to withstand up to 600 pounds weight.

Furthermore, it needs to be able that allows it to bend without breaking the middle.

Here’s a selection of the top wood that you can make use of for bed slats

Oakwood

Pinewood

Hickory

Birch

Ashwood

Beech

Make use of any and create the best of them, in their in their fre